The Doppler flowmeter uses the ultrasonic Doppler principle for measurement. It does not require cutting the pipeline to install a pipe segment sensor like the electromagnetic flow meter, nor does it require the use of a flow interception device. It also does not require the installation of a fixed weir to control the water flow for measurement. It can measure in both clear and muddy water.

1. Product Features

(1) The sensor supports instantaneous flow and cumulative flow;

(2) It can measure the flow rate of still water;

(3) It can measure the flow rate of partially full pipes, full pipes and open channels;

(4) It can measure the flow rate of circular, rectangular, trapezoidal and triangular cross-sections;

(5) The flow rate measurement range is wide, 0 ~ 10m/s, bidirectional;

(6) The flow rate measurement accuracy is high, with an error of 1mm/s;

(7) The ultrasonic level measurement has high accuracy, with an error of 1mm (within 2m);

(8) Pure physical method measurement, no calibration required;

(9) It supports static pressure level measurement;

(10) It supports temperature compensated flow rate measurement and level measurement;

(11) It supports RS485 ModbusRTU protocol;

(12) The sensor protection level is IP68 and supports long-term underwater operation;

(13) Online solution: display or RTU + sensor + special bracket;

(14) Portable solution: sensor + handheld device + measuring rod, and the suitcase can accommodate all accessories.

2. Industry Application

(1) Applicable to water level, flow rate and flow monitoring in irrigation areas, rivers, reservoirs and open channels;

(2) Applied to sponge cities, water supply/drainage networks, and black and smelly water bodies;

(3) Flow field analysis, liquid level detection and other scenarios for scientific research;

(4) Agricultural irrigation, sewage treatment, hydrology and water conservancy, urban road and bridge waterlogging monitoring and analysis, etc.

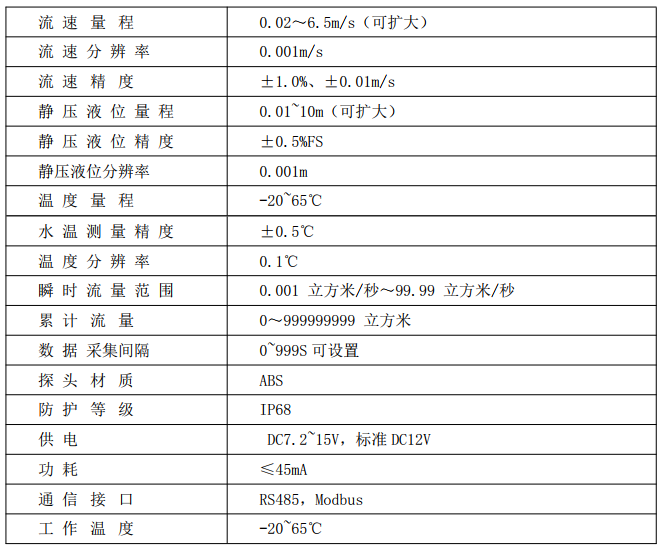

3. Technical parameters

4. Installation Instructions

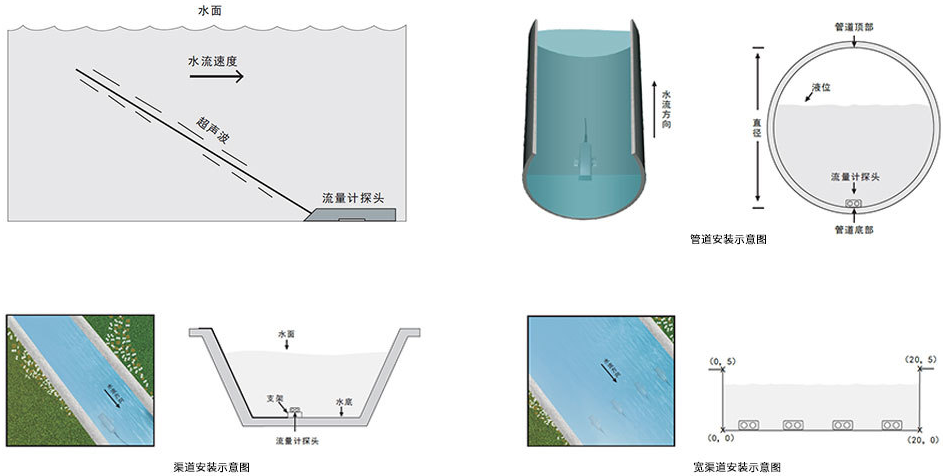

For installation, choose a long straight section with stable flow. Upstream of the flow meter, there should be a straight channel (pipe) 10 times the width of the channel (pipe); downstream of the flow meter, there should be a straight channel (pipe) 5 times the width of the channel (pipe).

The equipment is installed against the water flow, and at the same time, ensure that the equipment is parallel to the water flow direction. Generally, the flow meter is installed in the middle of the channel and pipeline.

1 If the installation site conditions permit, the flow meter can be directly fixed to the bottom of the channel or the bottom of the pipe with expansion bolts.

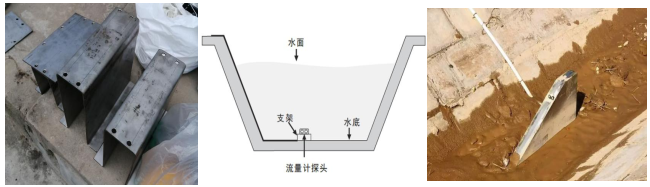

2 Fix the equipment with L-shaped brackets

① The connection points of each node of the L-shaped rod must be welded and fixed, and screws cannot be used. ②

The two right-angled sides of the L-shaped rod must be connected with metal rods of the same material as the L-shaped rod to achieve the function of supporting ribs.

③ To avoid resonance, it is recommended to pad 1mm thick rubber between the equipment and the L-shaped fixed metal plate.

④ Use expansion bolts to firmly fix the L-shaped bracket to the channel wall or pipe wall.

3 Flowmeter cable protection

DN20 galvanized steel pipe can be used to protect the cable to prevent water flow impact from damaging the cable.

4 Flowmeter pad installation

When the channel bottom and pipe bottom are seriously silted up on site, the equipment must be installed above the siltation layer. The installation parts should be streamlined as much as possible to reduce the impact on the flow state.