LWULA ultrasonic open channel flowmeter is a non-contact instrument that uses the principle of sound wave reflection to detect the liquid level in the water measuring weir and obtains the water flow through the weir by conversion. The instrument consists of an ultrasonic probe and a host, both of which are all plastic sealed structures. It can be widely used in industries such as industry and environmental protection to accurately detect open channel flow.

1. Product Features

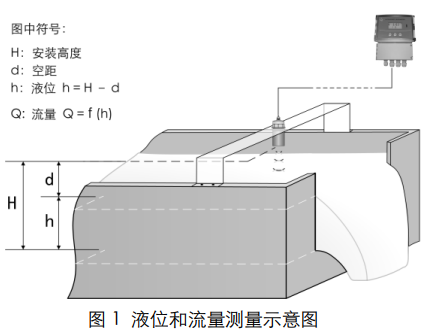

The instrument consists of an ultrasonic probe and a host, both of which are all plastic sealed structures. The ultrasonic probe is installed on the upper part of the weir (see Figure 1). It periodically emits a beam of ultrasonic waves to the liquid surface. After the sound wave reaches the liquid surface, it is reflected and received by the probe. The host measures the propagation time t of the process. According to the known sound speed v, the distance d (distance measurement value) from the liquid surface to the probe can be obtained. Under the premise of knowing the distance from the probe to the bottom of the weir, that is, the installation height H, the liquid level height h can be converted. According to the determined weir type, the host can obtain the flow value according to the liquid level.

The main performance characteristics are as follows:

☆ The open channel flow rate is detected with an accuracy of 1mm along with the liquid level. The open channel flow rate changes with every 1mm change in the liquid level. The detection accuracy is higher and the flow measurement is more accurate.

☆ Built-in multiple weir types: National standard-Parshall flume 1~25, triangular weir 90°, rectangular weir (25, 50, 75, 100cm).

☆ You can enter custom mathematical formula flow relationship.

☆ Large screen with backlit graphic LCD display, Chinese/English optional menu system.

☆ The flow unit can be set, the cumulative full scale can be customized, and the cumulative flow is saved when the power is off.

☆ The ultrasonic probe is fully enclosed and resistant to strong corrosion

☆ Low blind area, high sensitivity, high stability, strong anti-interference ability☆ Can provide up to 6 relay switch signals

☆ Can provide MODBUS-RTU digital signal

☆ The distance between the host and the ultrasonic probe can reach 1000 meters

☆ AC or DC power supply is optional

☆ Remote controller can be provided to set parameters for easy operation.

2. Industry Application

Used in industries such as industry and environmental protection to accurately detect open channel flow.

3. Technical parameters

(1) Host

| Liquid level resolution: 1mm |

| Level error: 1mm or 0.2% of full scale (calm water surface) |

| Display mode: Graphic LCD (with backlight) |

| Parameter setting method: 3-digit touch buttons (handheld operator optional) |

| Instantaneous flow display range: 0.000-999999L/S or m3/h or m3/min (automatic adjustment) |

| Maximum cumulative flow rate displayed: 99999999.9 m3/h |

| Analog signal output: one channel DC4-20mA current, corresponding to instantaneous flow |

| Load resistance: 0 ~ 500Ω |

| Digital communication: RS485 serial communication, standard MODBUS-RTU protocol |

| Relay output: upper and lower limit alarm and control (instantaneous flow and water level) |

| Relay mode: Normally open/normally closed (settable) |

| Number of relays: up to 6 |

| Relay specification: 5A 250VAC/30VDC |

| Power supply: DC: DC24V (±10%) 0.2A |

| Power supply: AC: AC220V (±20%) 0.1A |

| Ambient temperature: -40℃ -+75℃ |

| Shell material: ABS |

| Housing protection grade: IP67 |

| Cable gland: PG9/PG11/PG13.5 |

| Installation method: wall mounted |

| Dimensions: 250x185x125mm |

(2) Probe

| Measuring range: 0.00-4.00m (liquid level) |

| Blind area: 0.20m |

| Operating temperature range: -40℃ ~ +75℃ |

| Housing protection grade: IP68 |

| Shell material: ABS/PVDF |

| Probe withstand voltage range: 0.07MP~0.3MP (abs.) |

| Probe lead cable: standard length is 10 meters (can be extended to 1000 meters) |

| Probe transmitting beam angle: 8° (3db) |

| Installation method: thread, flange, bracket |

4. Installation Instructions

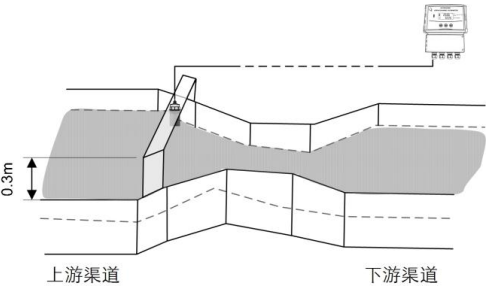

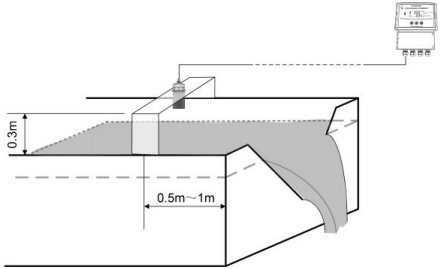

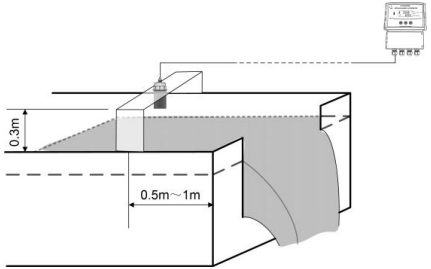

The ultrasonic probe should be installed above the water measuring weir. The probe emitting surface should be aimed at the water surface and can be adjusted with a level ruler. For Parshall flume water, the probe is installed at a distance of 2/3 of the contraction length from the throat; for triangular weirs and rectangular weirs, the probe is installed on the upstream side, 3 to 4 times the maximum water depth over the weir plate.

If the water surface fluctuates violently and affects the water level measurement; or if the water level measurement accuracy needs to be improved, a still water well can be used. The clean water well is connected to the bottom of the weir to measure the water level in the well.

When ultrasonic waves are emitted, they have a very small diffusion angle. If there are other objects blocking the diffusion angle, reflection will occur. If the reflection is very strong, it will cause measurement errors. However, the smooth and flat vertical weir sidewalls will not reflect ultrasonic waves transmitted from above.

Special tips:

(1) The ultrasonic probe should be pointed vertically toward the water surface.

(2) The maximum water level in the weir must not enter the blind area of the ultrasonic probe.

(3) There should be no debris on the water surface at the measuring point.

(4) The ultrasonic probe should not be too close to the side wall of the weir to avoid the sound waves being reflected by the upper part of the weir or the sloped side wall, so as to ensure that the water level at the lowest point of the weir can be measured.

(5) The lead-out cable of the ultrasonic probe cannot be used to fix the probe. The ultrasonic probe is installed on the Parshall trough, right-angle triangular weir, and rectangular weir as shown in the figure.