LWLD sanitary clamp electromagnetic flowmeter measures flow according to Faraday's law of electromagnetic induction. The advantages of electromagnetic flowmeter are extremely small pressure loss and a wide range of measurable flow. The ratio of maximum flow to minimum flow is generally above 20:1. It is applicable to a wide range of industrial pipe diameters. The output signal and the measured flow are linear, with high accuracy. It can measure liquids with conductivity ≥5μs/cm.

The clamp installation method of LWLD electromagnetic flowmeter has the advantages of easy installation and cleaning, and is often used in food production, pharmaceutical industry drug measurement, water purification monitoring and other occasions.

1. Product Features

(1) The use of new sanitary lining materials prevents the accumulation of measuring medium residues in the measuring tube;

(2) The measuring tube has no obstructing moving parts, no pressure loss, and low straight pipe section requirements;

(3) The sensor adopts a new generation of dedicated lining technology and uses a special mirror-polished PFA lining;

(4) The intelligent converter can simultaneously display measurement data such as volume flow percentage, instantaneous flow, and cumulative flow;

(5) The electromagnetic flowmeter adopts a quick connection solution, which is easy to disassemble, maintain and clean. The intelligent converter uses a liquid crystal backlight LED display, which can read clearly even in strong light or at night.

2. Industry Application

It can be widely used in the production process of mineral water, soy sauce, jam, beer, juice, rice wine, milk and other foods as well as in the fields of sanitation, chemical industry, etc.

3. Technical parameters

Nominal diameter | DN10mm~DN200mm | |

Accuracy | ±0.5% of the indicated value; ±0.3% or ±0.2% of the indicated value can be selected | |

Lining material | Food grade hard rubber; F46; PFA | |

Electrode Materials | SUS316; Hastelloy B/C | |

Electrode form | Standard | |

Connection | Clamp connection | |

Medium temperature | All-in-one | -10℃~+60℃ |

split type | -10℃~+160℃ | |

Nominal pressure | 0.6-1.6Mpa | |

Ambient temperature | -25℃~+60℃ | |

Ambient humidity | 5~100%RH (Relative humidity) | |

Dielectric conductivity | ≥20μs/cm | |

Measuring range | 1500:1 Flow rate setting <15m/s | |

Structural form | Integrated type; split type | |

Protection level | IP65; IP68 optional | |

Explosion proof sign | Ex db mbⅡCT6Gb | |

Product Standards | JB/T9248-2015 Electromagnetic Flowmeter | |

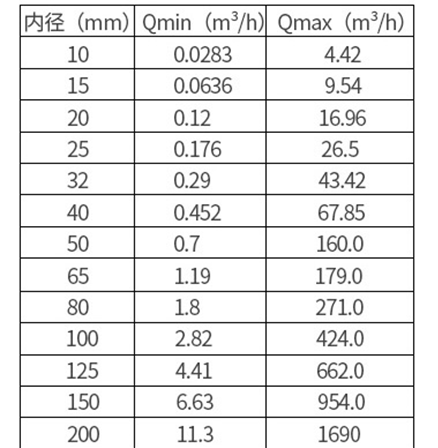

4. Product caliber and flow range comparison table

5. Installation instructions and instructions

(1) Places without vibration and strong electromagnetic fields (such as near large motors and inverters);

(2) Install vertically as much as possible. Horizontal installation needs to be installed at a low place and not at the top of the pipe to ensure that the pipe is full and prevent bubbles;

(3) The straight pipe section requirement is to ensure that the front section is 10 times the pipe diameter and the rear section is 5 times the pipe diameter;

(4) When installing by welding, be careful not to connect the instrument by welding to avoid damaging the flow meter;

(5) The outer shell should be grounded as much as possible, the shielded wire should be grounded at one end, and the connection point should not be grounded with strong electricity;

(6) For easy maintenance, the installation location needs to be selected to meet maintenance requirements. At the same time, a bypass pipe can be installed so that the fluid can flow through the bypass pipe in case of failure;

(7) Avoid direct sunlight and high temperature, and make sure to install it in a waterproof and moisture-proof manner;

(8) Other requirements that should be considered: signal lines should not be routed together with high-voltage lines.