The working principle of LWLD insertion electromagnetic flowmeter is based on Faraday's law of electromagnetic induction. In the electromagnetic flowmeter, the conductive medium in the measuring tube is equivalent to the conductive metal rod in the Faraday test, and the two electromagnetic coils at the upper and lower ends generate a constant magnetic field. When the conductive medium flows through, an induced voltage is generated. The insertion electromagnetic flowmeter is particularly suitable for measuring liquid fluids in medium and large diameter pipelines.

1. Product Features

(1) The measurement accuracy is not affected by changes in liquid density, viscosity, temperature, pressure and conductivity;

(2) High reliability external plug-in installation method. The sensor can be installed and maintained without removing the measuring tube. Therefore, it is more suitable for on-site use where water supply cannot be stopped. Moreover, it can be installed on-site in the old pipe.

(3) The structure is simple, the electromagnetic flowmeter measuring tube does not need a lining, and the reliability is high; the nominal diameter range is wide, suitable for all diameter pipes between DN100-DN3000;

(4) Integrated grounding electrode to achieve good grounding of the instrument; the sensor adopts new processing technology, solid-state packaging, vibration resistance, anti-penetration, and long life, so that the instrument has good measurement accuracy and stability.

2. Industry Application

Petroleum, chemical, steel, food, electricity, papermaking, metallurgy, water supply and drainage, petrochemical, medical and other industries.

3. Technical parameters

Nominal diameter | DN100~DN3000mm | ||

Accuracy | ±1.0% of indicated value | ||

Lining material | Polytetrafluoroethylene; PFA; F46; Neoprene; Polyurethane rubber; High temperature rubber | ||

Electrode Materials | SUS316; Hastelloy B/C | ||

Electrode form | Standard | ||

Connection | Plug-in connection | ||

Working conditions | All-in-one | -20℃~+60℃ | |

Split type | Neoprene lining; Polyurethane lining | -20℃~+60℃ | |

-20℃~+120℃; -20℃~+180℃ | -10℃~+160℃ | ||

Nominal pressure | 1.6MPa | ||

Ambient temperature | -25℃~+60℃ | ||

Ambient humidity | 5~100%RH (Relative humidity) | ||

Dielectric conductivity | ≥20μs/cm | ||

Measuring range | 1500:1 Flow rate setting <15m/s | ||

Structural form | Integrated type; split type | ||

Protection level | IP65; IP68 optional | ||

Product Standards | JB/T9248-2015 Electromagnetic Flowmeter | ||

4. Selection of electrodes and linings

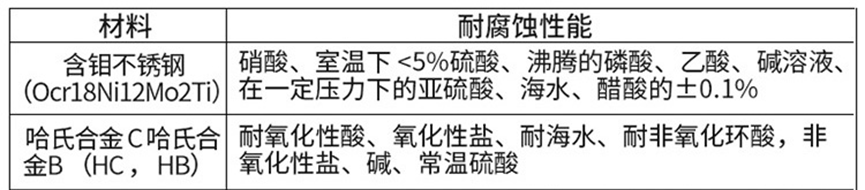

(1) Selection of electrodes

(2) Lining selection

5. Installation instructions and instructions

(1) General requirements

a. In order to facilitate installation, maintenance and upkeep, sufficient space must be reserved around the flow meter.

b. Avoid installing the flow meter in places where the temperature changes greatly or is exposed to high temperature radiation from the equipment.

c. The flow meter should be installed indoors. If installed outdoors, avoid direct sunlight. If necessary, install a sunscreen.

d. Avoid installing the flow meter in an environment containing corrosive gases.

e. Avoid installing the flow meter in places with strong vibration sources or strong magnetic fields.

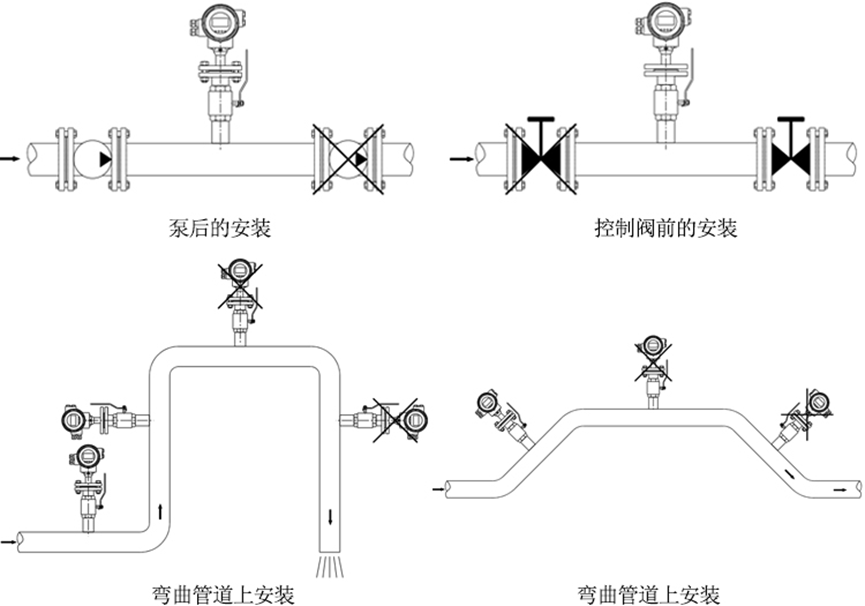

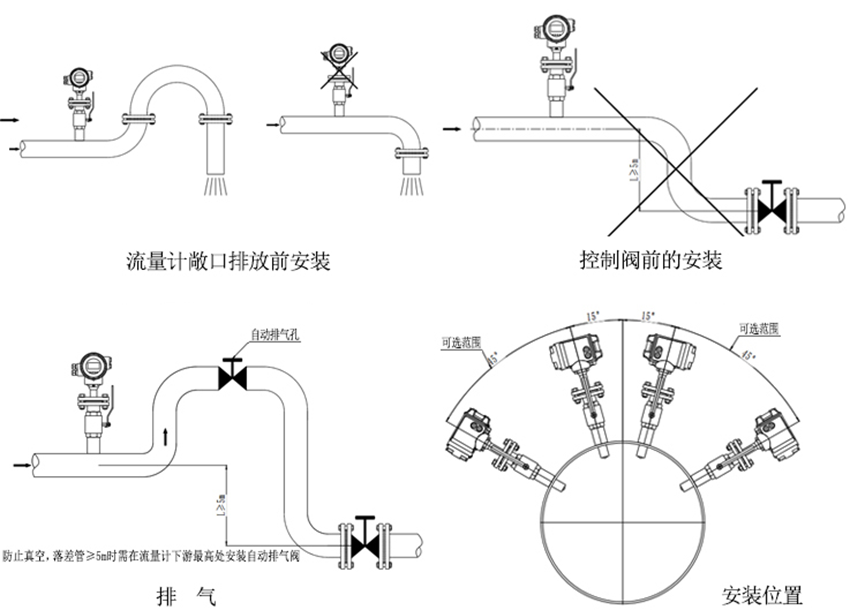

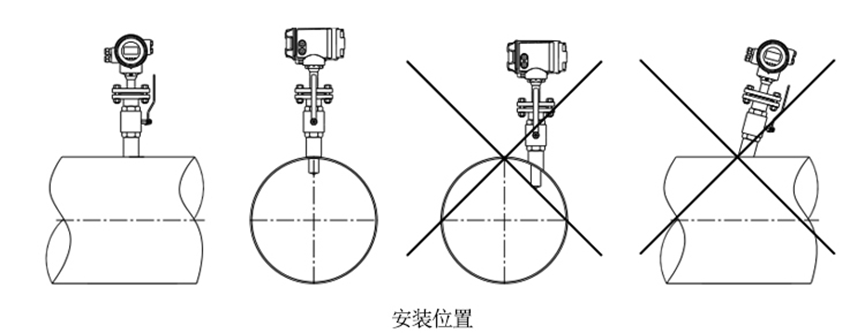

(2) Installation conditions Using straight pipe sections can prevent the medium from generating eddy currents or distortion due to the influence of elbows, TT-type tees, stop valves, and reducers.