The LWTMF series thermal gas mass flow meter is an instrument that uses the principle of thermal diffusion to measure gas flow. The sensor consists of two reference-grade thermal resistors (RTDs). One is the velocity sensor RH, and the other is the temperature sensor RMG that measures the temperature change of the gas. When these two RTDs are placed in the measured gas, one sensor RH is heated, and the other sensor RMG is used to sense the temperature of the measured gas. As the gas flow rate increases, the airflow takes away more heat, and the temperature of the sensor RH decreases.

1. Product Features

(1) Easy installation and maintenance, two-way detection, anti-vibration;

(2) Up to 24-point flow measurement;

(3) Correction of output analog quantity;

(4) Multi-point nonlinear curve correction;

(5) Wide range ratio 100:1;

(6) Flow rate and temperature are detected simultaneously and switched for display;

(7) Large-caliber small flow measurement, can be used for leak detection;

(8) Using proprietary technology "double balance structure" to package the sensor;

(9) Proprietary high humidity and high temperature algorithm, the medium temperature can reach 500℃;

(10) Direct mass flow detection, no need for temperature and pressure compensation.

2. Industry Application

Common steady-state gases (unstable media such as acetylene cannot be measured), process control and gas flow measurement of gas production and use in petroleum, chemical industry, metallurgy, electricity, water treatment, papermaking, food, medicine, cement, textile and production, scientific research units.

3. Technical parameters

| performance | Technical Parameters | |

| Structural form | Plug-in | Pipeline |

| Measuring medium | Various gases (except acetylene) | |

| Pipe diameter range | DN32 and above | DN15~DN200mm |

| Flow rate range | 0.1~120Nm/s | |

| Accuracy | ±1~2.5% | |

| Operating temperature | Sensor: -40℃~+220℃ Converter: -20℃~+45℃ | |

| Work Pressure | Medium pressure ≤2.5Mpa | Medium pressure: 4.0Mpa |

| Power supply | DC24V or AC220V≤18W | |

| Response speed | 1s | |

| Output signal | 4-20mA (photoelectric isolation, maximum load 500Ω), pulse, RS-485 (photoelectric isolation), HART protocol | |

| Call the police | 1-2 relay normally open contacts, 10A/220V/AC, 5A/30V/DC | |

| Supply Type | Split structure, integrated structure | |

| Pipe material | Carbon steel, stainless steel | |

| On-site display | Four-line Chinese character LCD display | |

| Display content | Mass flow, standard volume flow, cumulative flow, standard time, cumulative running time, standard flow rate, etc. | |

| Protection level | IP65 | |

| Sensor Material | Stainless steel | Stainless steel, carbon steel |

4. Product caliber and flow range comparison table

5、安装说明

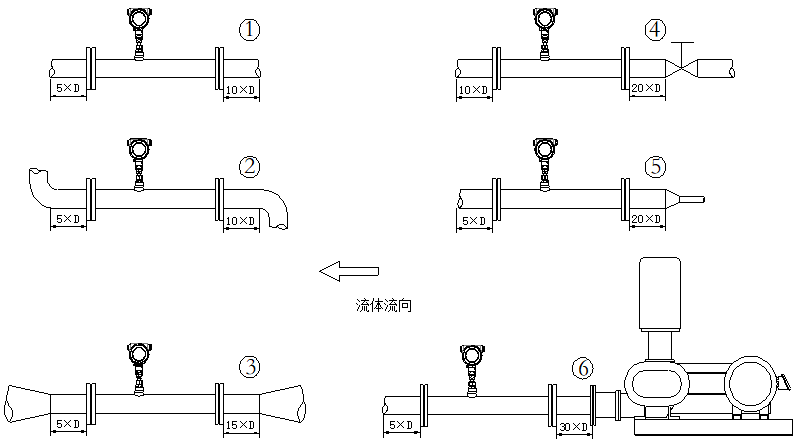

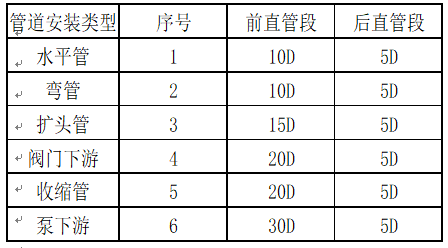

(1)安装仪表时应远离弯头,障碍物,变径,阀门,以保证有一个稳定的流场,一边要求有一个较长的上限直管道,前直管道长大于10D,后直管段长大于5D.下图为现场经常遇到的几种情况所要求的直管段长度 :

Straight pipe section diagram before and after installation

(2) When the straight pipe section requirements cannot be met on site, a gas rectifier can be connected in series to significantly reduce the straight pipe section requirements.